Australian Utility Company Customer Story

CLIENT:

Western Australian Power Company

Australia’s energy networks are vital infrastructure, powering homes, businesses, industry and, more recently, vehicles. They ensure essential services, our standard of living and indirectly contribute to Australia’s economic prosperity.

As Australia's economy and population grows, so too does the demand for reliable energy. Safety in all aspects of a utility company’s operations contributes to reliable energy delivery.

MAX-SAFE Solutions are making this major utility company in Western Australia safer, benefiting staff, the general public and all those who rely on them for electricity.

Scott McPherson

Managing Director, SGESCO-MAX

Snapshot

A major Western Australian electrical utilities company has become the first in Australia to improve the safety of its fleet with the MAX-SAFE Anti-Rollaway Brake Solution and the MAX-SAFE Reverse Watch Solution from Brisbane-based heavy vehicle safety specialist, SGESCO-MAX.

The solutions protect staff, vulnerable road users and the public, as well as vehicles and property from accidental vehicle rollaways, and from reversing accidents caused by vehicle blind spots.

Read on for details on:

- The environment overview

- The safety challenge

- The solutions

- The rollout

- The training

- Feedback & the future

- Key benefits

-

Environment Overview

Energy is vital infrastructure for homes, communities and businesses across Australia and a major operating cost for all sectors of society. Ensuring cost-effective supply is a key requirement for those in the industry with companies expected to operate safely, economically and efficiently as the cost of doing business impacts the cost that is paid for electricity.

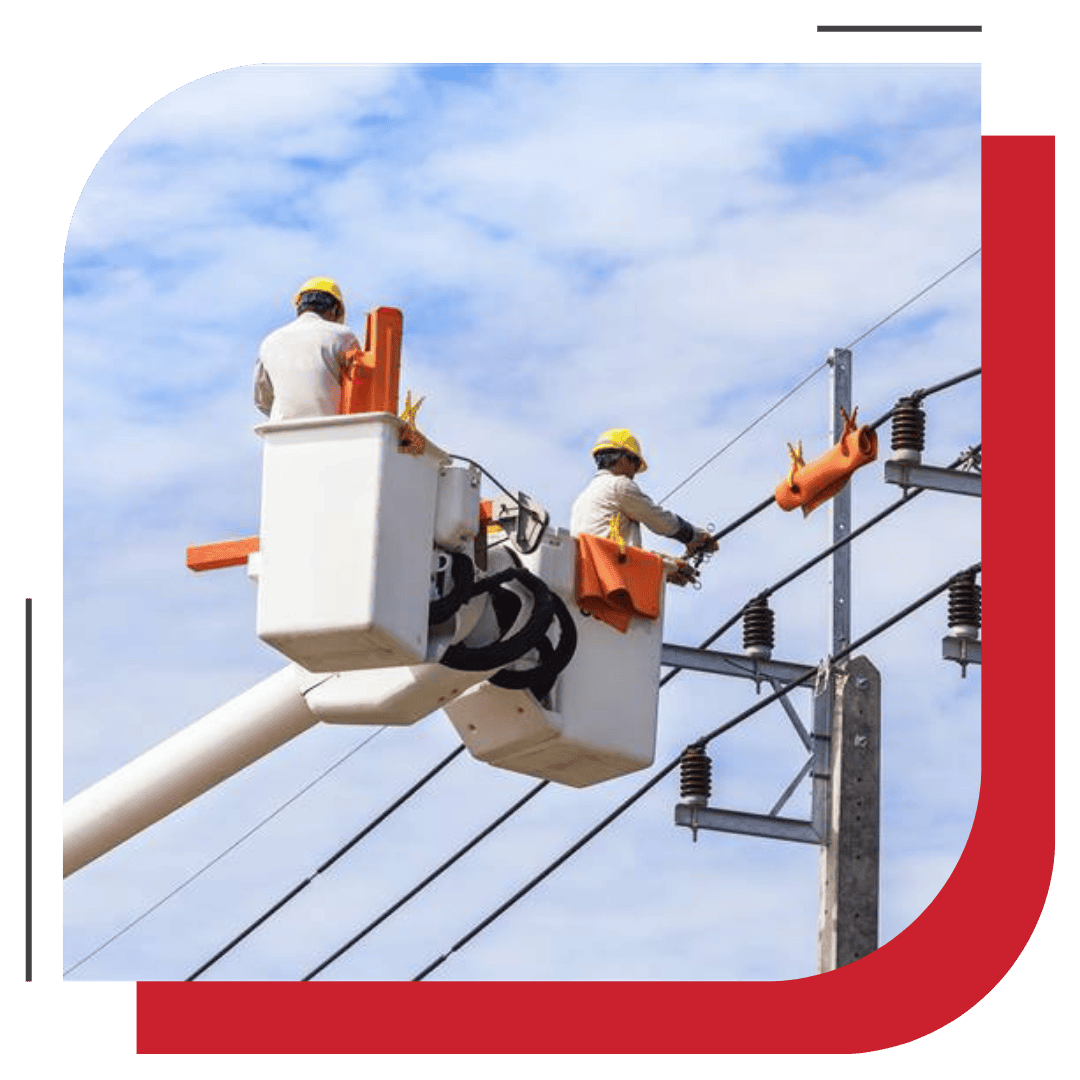

This WA electrical utilities company operates in the south-west area of Western Australia, with trucks and operators working across remote and rural areas, farmland and metropolitan locations. Many of their vehicles have boom lifts and baskets, e.g., Elevating Work Platforms (EWPs), operated via an articulated arm. They are used in work projects that involve essential maintenance such as replacing poles, upgrading network infrastructure including crossarms, transformers and insulators, and installing high-voltage powerlines.

-

The Safety Challenge

Heavy vehicle rollaways are dangerous and, surprisingly, more common than one would think. Often human error in not applying the park brake properly is the main reason for such calamities. Rollaway vehicles can leave a path of destruction in their wake with often the biggest risk being to staff who try to climb into a vehicle while it is moving to stop it. A vehicle rollaway that would result in hitting a power pole could do significant damage to the vehicle and impact supply.

On top of the standard operating environment, with extreme weather events on the rise, there are increasingly more calls on utility companies to ensure energy supply. This can add to the pressures of such work, with a sense of urgency around work delivery and also the challenge of ensuring power during turbulent weather and or smoke, at night or while working outside on extremely hot or windy days.

For utilities companies that have staff working several metres above ground in an Elevating Work Platforms (EWP), having on-ground vehicle stability is essential for safety.

Removing known safety risks around a vehicle makes good business sense and is paramount for organisations that have safety as a core value.

-

The Solutions

The MAX-SAFE Anti-Rollaway Brake Solution provides an active safety solution in the event of a driver neglecting to fully apply the park brake before leaving their vehicle or, if for some reason, the park brake does not hold as expected. It prevents vehicle rollaways and the damage they can cause.

Introduced in 2000, the solution is used extensively in the Australian waste management industry. In 2021 New Zealand utilities company, Connetics, became the first NZ utility company to trial and deploy the solution. As of 2024 MAX-SAFE Anti-Rollaway is installed on approximately 90 of their high-risk heavy vehicles including ones with cranes at the rear, boom lifts and Elevating Work Platforms (EWP).

First introduced in 2010, MAX-SAFE Reverse Watch has reversing sensor technology to monitor the large blind spot behind a mid to large commercial vehicle for obstacles or people. It sees what drivers can’t. A major upgrade – 2.0 – in 2023 extended the capabilities of the radar to cover up to 6 metres behind a vehicle and 10 metres across, as well as provide collision detection of approaching objects. The radar connects to an in-cabin LCD screen that provides specific controls. Importantly, the solution can work with an OEM’s electronic park brake or engage the MAX-SAFE Anti-Rollaway Braking system to suddenly brake a vehicle – before a driver has time to react – thereby preventing accidents with people or objects.

Both solutions have saved countless lives over the past two decades.

-

The Rollout

The WA utilities company investigated MAX-SAFE solutions and based on recommendations and a value / needs assessment opted to install the solutions without trial.

To date, both solutions have been installed on 20 new MAN trucks and Isuzu F series vehicles over the past 12 months. Their intention is to install the MAX-SAFE Anti-Rollaway Brake Solution and MAX-SAFE Reverse Watch on all heavy vehicles in the fleet – approximately 200 – as they are replaced over the next five to seven years.

SGESCO-MAX staff liaised with the engineers of the body building companies for the respective vehicle brands (MAN and Isuzu) to ensure a suitable mounting area for the Reverse Watch radar was inbuilt as part of the body during manufacturing.

The installations of both MAX-SAFE solutions were completed by SGESCO-MAX dealers in Perth, namely Delta Auto Spark for the MAN vehicles and Major Motors Isuzu.

-

The Training

SGESCO-MAX provided two types of training as part of the rollout.

As the client would be maintaining the vehicles and safety solutions in-house, SGESCO-MAX provided all their maintenance lifecycle information for upload to the client’s online training system for vehicle maintenance. This provides them with the schedule of maintenance over a seven-year period and what is required for each maintenance service, which also includes testing the systems to ensure they are operating as intended.

Driver training in both safety solutions was provided by online training via SGESCO-MAX’s Teams portal, allowing for self-paced training for the staff involved. The training overviews the operations of both safety solutions and what drivers need to know and provides quizzes throughout to ascertain learning and comprehension. Because both solutions can brake the vehicle, operators need to know how to override the system, when it is safe to do so, and ensure it is set up to continue to monitor safety and respond to any risks as intended. At the end of the training a certificate is issued to show competency – this is an important component for a company’s compliance with Chain of Responsibility (CoR) obligations.

-

Feedback & The Future

“We are excited that a company within the WA utilities sector has recognised the value of our solutions and prioritised their installation to improve the safety of their fleet,” said Scott McPherson, Managing Director of SGESCO-MAX.

Given this was the first time this WA utility company had worked with SGESCO-MAX and we were based on the other side of Australia, we were pleased to hear that they were very happy with the support we provided in training all their staff, said Scott.

“We have had a dealer network in WA for over five years, servicing clients in the waste management, mining and T&L industries, so we are pleased that this experience and customer service made for a positive roll-out,” he said.

“Since this installation, other business with heavy vehicles operating within greater Perth have expressed interest in our solutions, and in improving their fleet safety and removing the costs to business that comes from accidents caused by blindspots and rollaways,” noted Scott.

-

Key Benefits

MAX-SAFE REVERSE WATCH SOLUTION

-

ASSISTANCE for the driver

-

PROTECTION of people and property

-

INSURANCE against driver oversight

-

ACTIVE BRAKING on detection of object

-

Both VISUAL ALERTS AND AUDIBLE WARNINGS

-

FAULT MONITORING and OVERRIDE CAPABILTY

-

DANGER ZONE is programmable

-

Complies with ADR 38/40 CLAUSE 4.32

-

Part of the MAX-SAFE SAFETY ECO-SYSTEM

MAX-SAFE ANTI-ROLLAWAY BRAKE SOLUTION

-

SAFETY OF PERSONNEL around the vehicle

-

PROTECTION of the vehicle and equipment

-

INSURANCE against driver oversight

-

CONTINUOUS MONITORING of multiple conditions

-

Both VISUAL alerts and AUDIBLE warnings

-

Intelligent logic with SELF-CHECKING to ensure system integrity

-

ADR COMPLIANT solution

-

QUEENSLAND GOVERNMENT APPROVED (TA.022 and TA.034)

-

Optional REVERSE WATCH MODULE for additional safety

- Part of the MAX-SAFE SAFETY ECO-SYSTEM

-